News

Only good news are good news.

October 2019

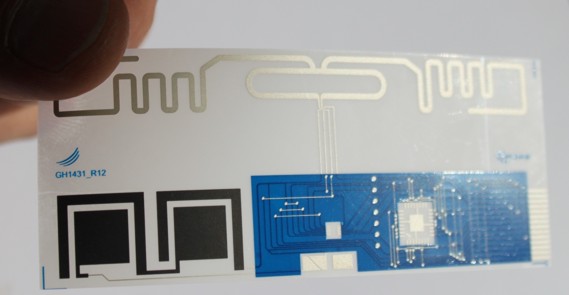

prelonic launches first own product: PIP - prelonic interactive paper

As a first own development, prelonic offers interactive paper.

PIP can be seen either as an extension of mobile devices to paper or as an upgrade of paper to an electronic interface. It allows to have direct interaction of mobile phones and paper via NFC.

The roll-out of this product will be started via partners in the marketing area.

June 2018

prelonic got mass assembly equipment for hybrid electronics.

Professional machinery for pick and place of SMD components down to 0402 and for ICs with pitches down to 0.35 mm has been aquired and installed.

Mass production in hybrid electronics requires fast assembly processes. Prelonic uses standard P&P equipment to populate PET, paper and cardboard substrates with SMD components

November 2017

prelonic moves to a new lab area

New lab are of 203 sqm has been rented and adopted to further develop the prelonic hybrid technology

Professional assembly machinery will be purchased to build up a pilot and mid volume line for hybrid assembly of classical electronics on PET, paper and cardboard substrates

February 2017

prelonic completed the hybrid assembly routes by soldering technologies

Isotropic and anisotropic glueing, what was used by prelonic for years is now accompanied by a soldering technology, which also allows to assemble chips with smalllest pin pitches.

This technology is a result of requirements in the IoT area, where reliable mass production processes have to be combined with low cost prints and substrates.

August 2013

prelonic developed an electrochormic display, which is printed in few simple printing steps, using commercial available materials.

The display is one-sided and solid-state, what means, that no lamination processes are necessary.

The employed processes and materials enable the probably cheapest electrochromic display in the world. prelonic will further work on formulation and optimization of materials and market the technology.

February 2013

prelonic works in co-operation with Nanyang Technology University on combined energy harvesting and storage - so called CEGS devices.

prelonic supports with know-how in product and process development to enable scalability and mass production.

Former experiance in the Pasteur project - which aimed data logging with battery integrated sensor devices - helps to create a competitive and cheap product.

September 2012

Electroluminescence is at the moment the only mature technology to enable printed flexible lamps and illuminate signage on packaging, paper and films.

The main disadvantage is the complex, expensive and bulky driver.

prelonic is working for two years now on the development of a printed EL driver and achieved a major progress in this topic.

In co-operation with the HTL Electronics department the printed EL driver was realized in its main parts. Some discrete parts are still necessary, which will be substituted subsequently. Also miniaturisation is going on.